Add to Cart

Hydrostatic Tested Inconel 625 Chemical Injection Line Capillary Coiled Tubing

Meilong Tube specially manufactures seamless and redrawn, welded and redrawn hydraulic control line capillary tube which are made from corrosion-resistant austenitic, duplex, super duplex stainless steels and nickel alloy grades. The tubing is used as hydraulic control lines and chemical injection lines specially serving oil and gas, geothermal industry.

Typical Size of Inconel 625 Chemical Injection Line

Outside diameter of chemical injection lines is mainly 3/8’’ (9.53mm).

Wall thicknesses: 0.035’’ (0.89mm), 0.049’’ (1.24mm), 0.065’’ (1.65mm), 0.083'' (2.11mm)

Control line tubing is available in lengths from 400 feet (122 meters) to 32,808 feet (10,000 meters). No orbitally butt welds.

Other specifications (1/8’’ to 3/4’’) are available on request.

Importance of Inconel 625 Chemical Injection Line

Each one nickel alloy Incoloy 625 tubing capillary tube is a completely continuous length without orbital welds.

Each one tubing coil is hydrostatic tested at minimum 10,150 psi.

The test can be witnessed on site by the third party inspectors (SGS, BV, DNV).

Other tests are eddy current test, chemicals, flattening, flaring, tensile, yield, elongation, hardness for the material quality.

Application for Inconel 625 Chemical Injection Line

Chemical Injection Line

A small-diameter conduit that is run alongside production tubulars to enable injection of inhibitors or similar treatments during production. Conditions such as high hydrogen sulfide [H2S] concentrations or severe scale deposition can be counteracted by injection of treatment chemicals and inhibitors during production.

A general term for injection processes that use special chemical solutions to improve oil recovery, remove formation damage, clean blocked perforations or formation layers, reduce or inhibit corrosion, upgrade crude oil, or address crude oil flow-assurance issues. Injection can be administered continuously, in batches, in injection wells, or at times in production wells.

Other Applications

Nickel alloy Inconel 625 tubing coil control line for chemical injection

Bare and encapsulated hydraulic control line coiled alloy tubing for subsea safety valves

Velocity strings, work strings, and steel tube umbilicals

Geothermal coiled alloy tubing

Alloys for Chemical Injection Line

| Alloy Tubing |

Hydraulic Control |

Chemical Injection |

Chloride Pitting / Crevice Corrosion Resistance |

H2S / CO2 Resistance |

Chloride Stress Corrosion Cracking (SCC) Resistance | UNS / ASTM Specification |

|

Stainless 316L – 170 MPa min. yield strength Seam-Welded Pressure Tubing |

• | • | S31603 / A269 | |||

|

Duplex 2205 – 485 MPa min. yield strength Seam-Welded Pressure Tubing |

• | • | • | • | • | S32205 / A789 |

|

Duplex 2507 – 550 MPa min. yield strength Seam-Welded Pressure Tubing |

• | • | • | • | • | S32750 / A789 |

|

Incoloy 825 – 240 MPa min. yield strength Seam-Welded Pressure Tubing |

• | • | • | • | • | N08825 / B704 |

|

Inconel 625 – 414 MPa min. yield strength Seam-Welded Pressure Tubing |

• | • | • | • | • | N06625 / B704 |

Chemical Injection Line Features

Close dimensional tolerances

Considerably enhanced mechanical properties

Superior surface finish

High cleanness of inside surface

Controlled ovality, eccentricity

Chemical Compositions of Inconel 625 for Nickel Alloy Chemical Injection Line

| Nickel | Chromium | Iron | Molybdenum | Columbium + Tantalum | Carbon | Manganese | Silicon | Phosphorus | Sulfur | Aluminum | Titanium | Cobalt |

| % | % | % | % | % | % | % | % | % | % | % | % | % |

| min. | max. | max. | max. | max. | max. | max. | max. | max. | max. | |||

| 58.0 | 20.0-23.0 | 5.0 | 8.0-10.0 | 3.15-4.15 | 0.10 | 0.50 | 0.5 | 0.015 | 0.015 | 0.4 | 0.40 | 1.0 |

Standard Equivalence

| Grade | UNS No | Euro Standard | |

| No | Name | ||

| Alloy | ASTM/ASME | EN10216-5 | EN10216-5 |

| 625 | N06625 | 2.4856 | NiCr22Mo9Nb |

Material Description

Inconel 625 is a material with excellent resistance to pitting, crevice and corrosion cracking. Highly resistant in a wide range of organic and mineral acids. Good high temperature strength.

Characteristics of Inconel 625

Excellent mechanical properties at both extremely low and extremely high temperatures.

Outstanding resistance to pitting, crevice corrosion and intercrystalline corrosion.

Almost complete freedom from chloride induced stress corrosion cracking.

High resistance to oxidation at elevated temperatures up to 1050C.

Good resistance to acids, such as nitric, phosphoric, sulfuric and hydrochloric, as well as to alkalis makes possible the construction of thin structural parts of high heat transfer.

Inconel 625 for Application

Components where exposure to sea water and high mechanical stresses are required.

Oil and gas production where hydrogen sulfide and elementary sulfur exist at temperature in excess of 150C.

Components exposed to flue gas or in flue gas desulfurization plants.

Flare stacks on offshore oil platforms.

Hydrocarbon processing from tar-sand and oil-shale recovery projects.

Nickel Alloy Tubing Weight per Meter (kg)

Inconel 625 (UNS N06625)

| O.D. | W.T. | |||||

| Fraction | Decimal | 0.028 | 0.035 | 0.049 | 0.065 | 0.083 |

| 1/8 | 0.125 | 0.0465 | 0.0539 | - | - | - |

| 1/4 | 0.250 | 0.1065 | 0.1288 | 0.1686 | 0.2059 | 0.2372 |

| 3/8 | 0.375 | 0.1663 | 0.2037 | 0.2733 | 0.3449 | 0.4149 |

| 1/2 | 0.500 | 0.2262 | 0.2785 | 0.3782 | 0.4839 | 0.5924 |

| 5/8 | 0.625 | 0.2862 | 0.3535 | 0.481 | 0.6231 | 0.7699 |

| 3/4 | 0.750 | 0.3460 | 0.4283 | 0.5879 | 0.7621 | 0.9475 |

Properties of Inconel 626 Nickel Alloy Chemical Injection Line

Seam-welded & floating internal plug redrawn tubing. Supplied in the annealed condition

Continuous length without orbital joint welds

| Alloy | UNS | O.D. | W.T. | Working Pressure | Burst Pressure | Collapse Pressure | Test Pressure | |

| inch | inch | inch | psi | psi | psi | psi | ||

| Inconel 625 | N06625 | 1/8 | 0.125 | 0.028 | 19,024 | 57,892 | 22,002 | 21,750 |

| Inconel 625 | N06625 | 1/8 | 0.125 | 0.035 | 23,780 | 72,365 | 27,503 | 27,550 |

| Inconel 625 | N06625 | 1/4 | 0.250 | 0.035 | 12,516 | 38,087 | 14,475 | 14,500 |

| Inconel 625 | N06625 | 1/4 | 0.250 | 0.049 | 18,065 | 54,969 | 18,869 | 20,300 |

| Inconel 625 | N06625 | 1/4 | 0.250 | 0.065 | 24,633 | 74,970 | 23,090 | 27,550 |

| Inconel 625 | N06625 | 3/8 | 0.375 | 0.035 | 8,043 | 24,482 | 10,182 | 9,425 |

| Inconel 625 | N06625 | 3/8 | 0.375 | 0.049 | 11,546 | 35,143 | 13,605 | 13,050 |

| Inconel 625 | N06625 | 3/8 | 0.375 | 0.065 | 15,829 | 48,182 | 17,202 | 18,125 |

| Inconel 625 | N06625 | 3/8 | 0.375 | 0.083 | 20,648 | 62,839 | 20,901 | 23,200 |

| Inconel 625 | N06625 | 1/2 | 0.500 | 0.049 | 8,433 | 25,657 | 10,588 | 9,425 |

| Inconel 625 | N06625 | 1/2 | 0.500 | 0.065 | 11,507 | 35,041 | 13,576 | 13,050 |

| Inconel 625 | N06625 | 1/2 | 0.500 | 0.083 | 15,010 | 45,700 | 16,733 | 17,400 |

| Inconel 625 | N06625 | 5/8 | 0.625 | 0.049 | 6,624 | 20,175 | 8,644 | 7,250 |

| Inconel 625 | N06625 | 5/8 | 0.625 | 0.065 | 8,788 | 26,763 | 11,467 | 10,150 |

| Inconel 625 | N06625 | 5/8 | 0.625 | 0.083 | 11,222 | 34,176 | 14,643 | 13,050 |

| Inconel 625 | N06625 | 3/4 | 0.750 | 0.049 | 5,518 | 16,806 | 7,200 | 6,525 |

| Inconel 625 | N06625 | 3/4 | 0.750 | 0.065 | 7,320 | 22,293 | 9,552 | 8,700 |

| Inconel 625 | N06625 | 3/4 | 0.750 | 0.083 | 9,348 | 28,469 | 12,197 | 10,875 |

Theoretical burst pressure based on minimum wall thickness, and minimum tensile strength

Theoretical collapse pressure based on minimum wall thickness, and minimum yield strength

Pressure rating at 100°F (38°C), neutral and static conditions

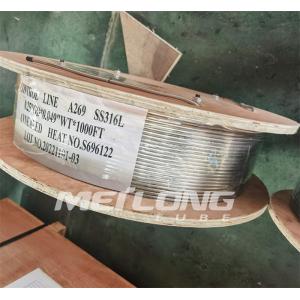

Tubing Process and Packing

Seamless- pierced, redrawn, annealed (multi-pass circulation process)

Welded- longitudinally welded, redrawn, annealed (multi-pass circulation process)

Packing- Tubing is level wound coiled on the metal / wooden drums or spools.

All drums or spools are packed in wooden crates for easy logistic operation.